Ender 3 V3 Plus remixed parts

Files provided are as-is with no guarantee that they work!

- Spring Arm Mod

- Vertical Drop Filament Holder

- Vertical Drop Filament Holder using 608 Bearings

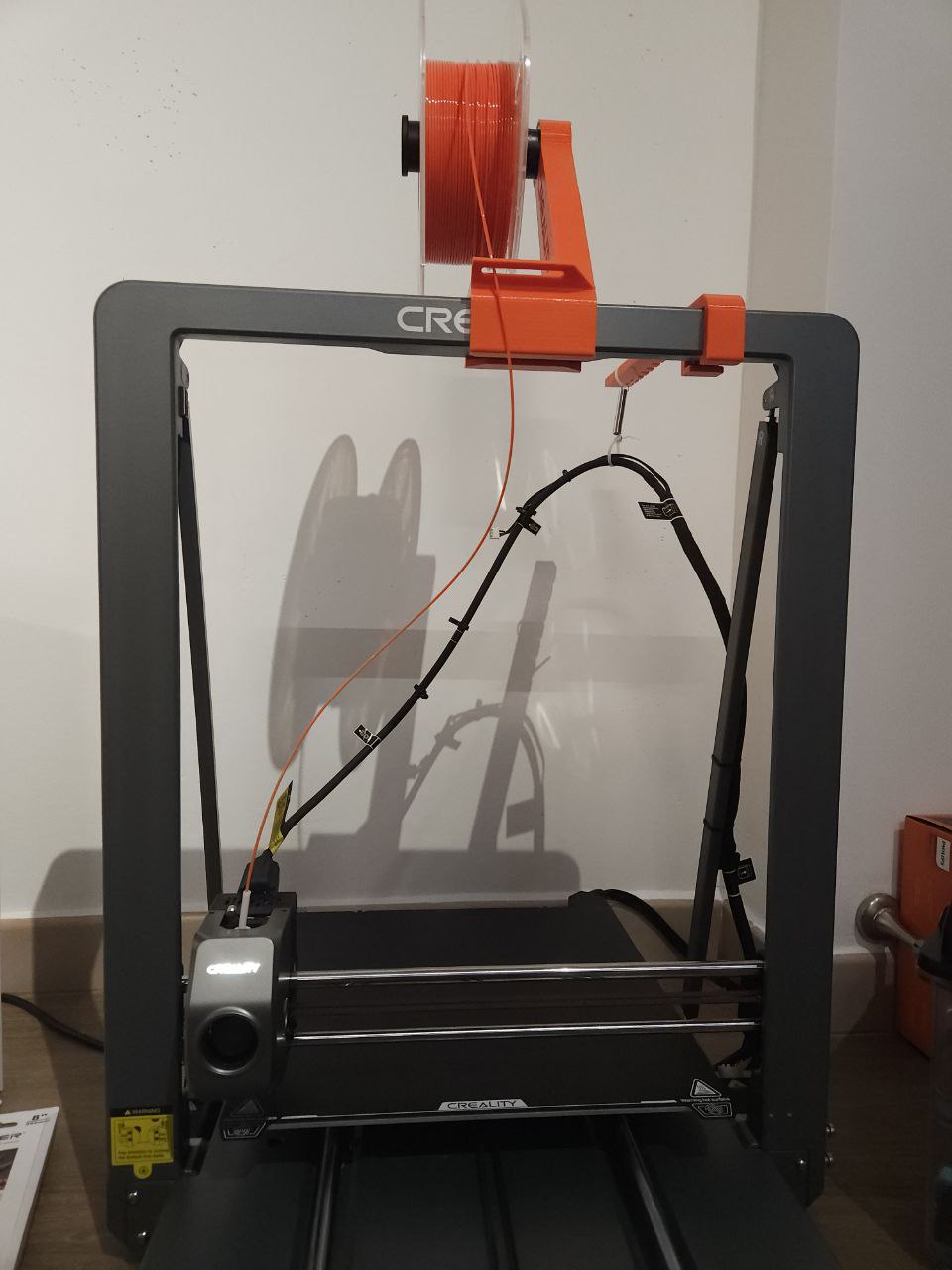

Spring Arm Mod

The Ender 3 V3 plus's print head cable occasionally gets jammed in this area when setup using the original layout.

What I've done is re-route the cable through the back. This seems to work well, but the cable can drag on the print bed. I've remixed this arm to hold up the cable.

Note that while I am using a tension spring, you can just use a bunch of zipties or a piece of string.

For the filament, I'm using the printable top-mount spool holder and only using a sliver of tubing.

The filament runout sensor is disconnected atm and it doesn't seem to affect prints. I don't have a way to extend the cable for it to work so that will be a project

for another time.

Here are the files for slicing: No supports required.

* I made up this version just in case folks with the regular V3 want to try this out.

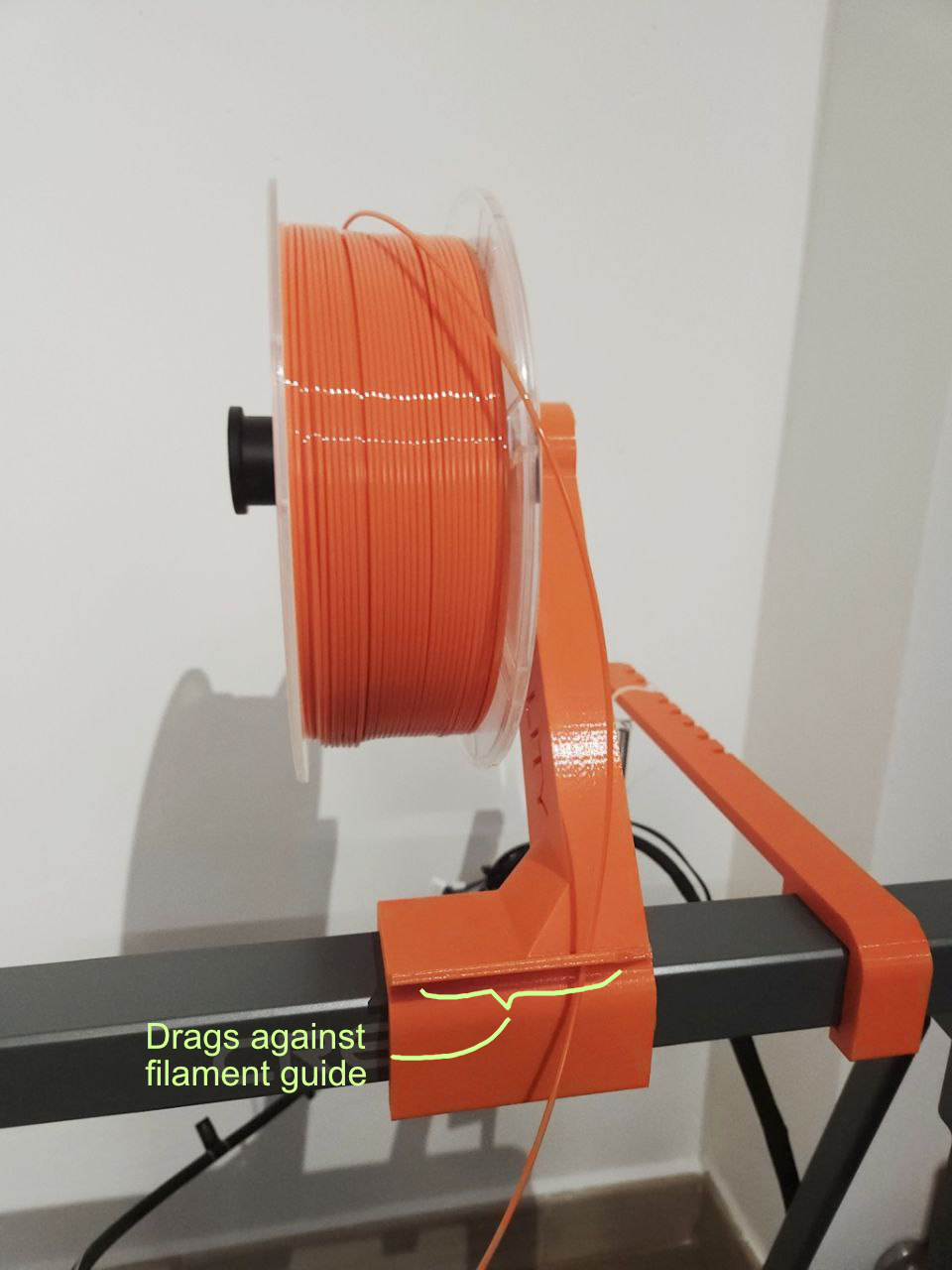

Vertical Drop Filament Holder

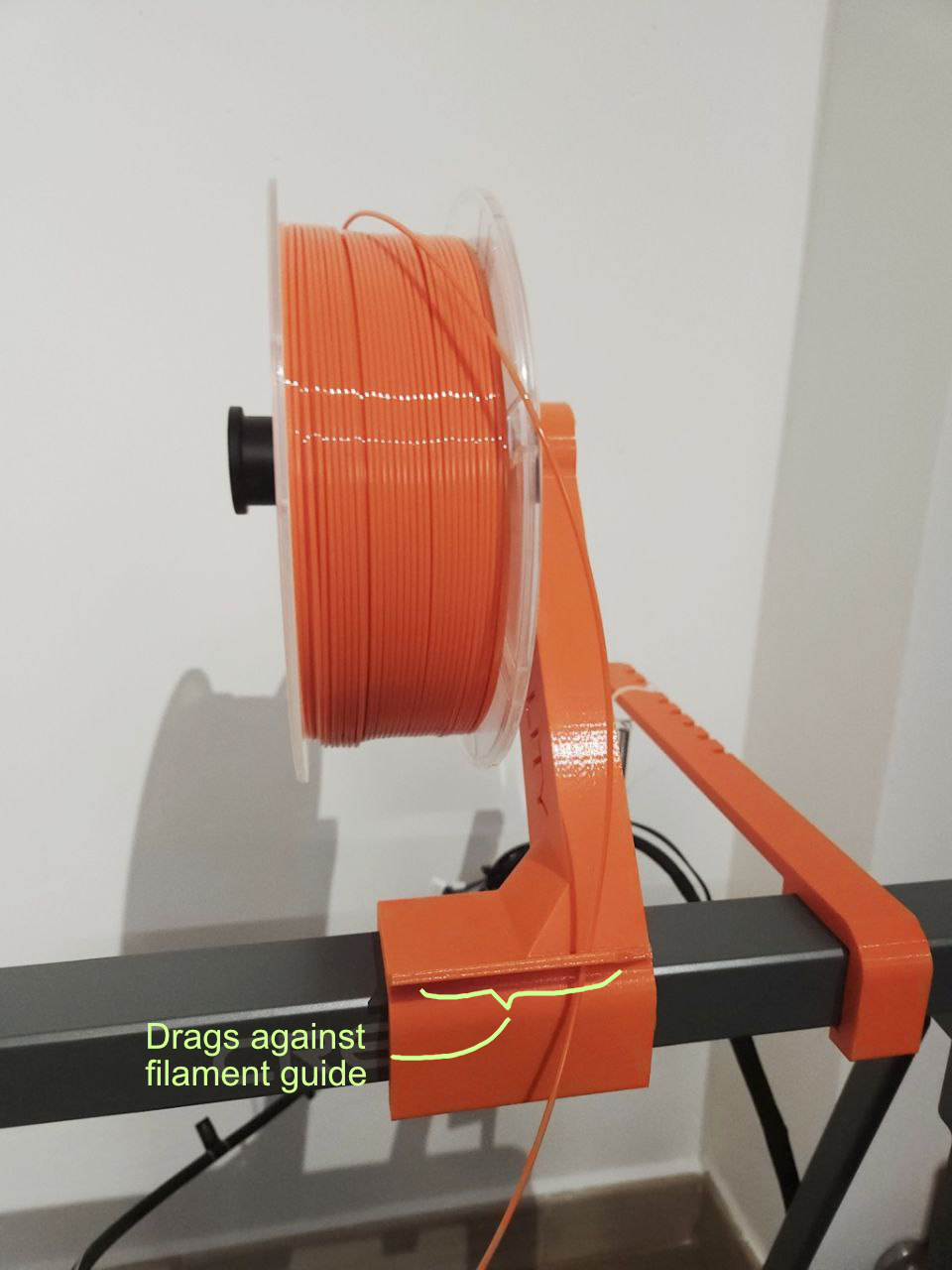

The top mount spool holder (it is a printable object found on the included thumb drive) is a much better option compared to the stock side mounted filament spool holder.

The side mounted holder is very fiddly to setup and it has jammed on me several times, as demonstrated very well in this video by 3DPrintSOS.

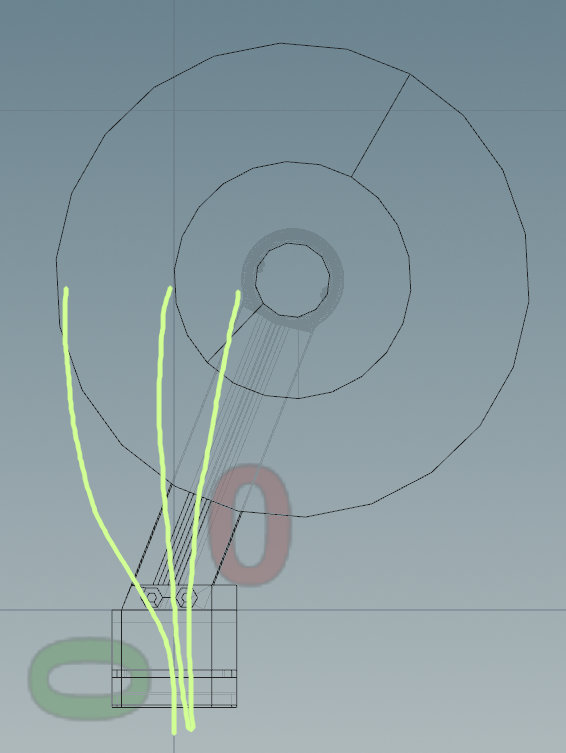

When filament is being extruded though, the filament rubs against the filament guide, and pulled left and right as the print head travels. I don't like this, and thought

if the spool was rotated, the filament would just travel straight down.

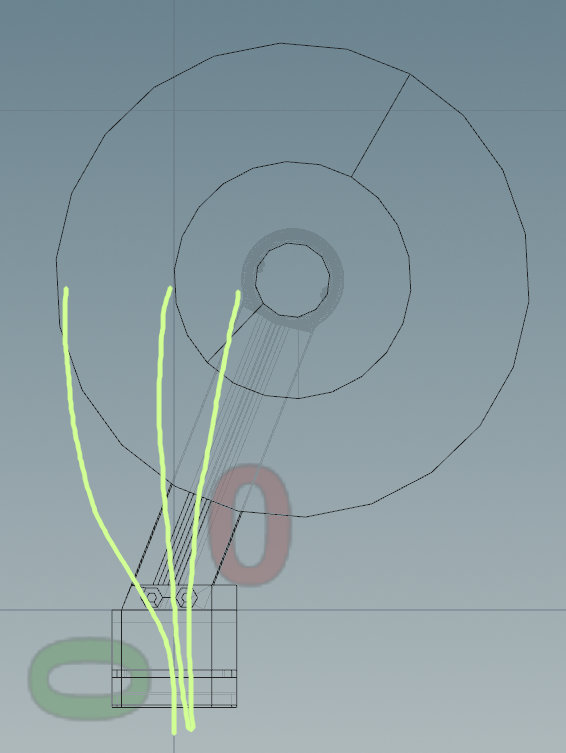

This is the concept/design I came up with. The spool is placed specifically so that no matter how much filament is there it should just travel down as much as possible with as little dragging.

M3 screws are required to connect the parts together.

Here are the files for slicing, supports are required for the top object.

2x 18mm M3 screws/nuts/washers are required to connect the parts together.

Vertical Drop Filament Holder using bearings

Primarily designed so that flexible filament (tpu for me) won't be over stretched when being extruded - the normal spool holder is just a tube to hold up the spool

and it tends to take a bit of pulling before the friction is overcome and the spool turns. Using ball bearings solves this issue. [ Video here ]

Here are the files for slicing.

- Bearing Holder Slide this through the bearings (Do not use a brim for this print, if you do, use mouse-ears. The brim adds too much stiffness to the "springs" unless you can clear the brim on the inside.

- Spool Holder Place the ball bearings with their holders in the grooves

- Main Arm

- Base

Note that I use the counterbore bridging in Orca Slicer to handle some of the screw holes.

Requires 4x 608 bearings and 4x M3 20mm machine screws and nuts.